INSPECTIONS & VALIDATIONS

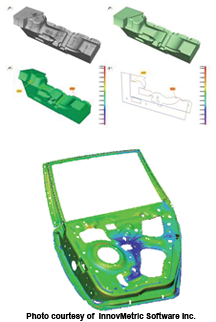

Our non-contact infra-red laser scanner generates over 23,000 data points per second creating a Point Cloud

of 3 Dimensional Data. This high precision data details information for items ranging from small medical devices

to large automotive and aerospace components. Rather than traditional inspection techniques, our digitally

scanned data provides 100% part or assembly surface capture, therefore, no features get missed during the

inspection process. Actual-to-CAD design intent is validated via a colour deviation/error map which provides

faster identification and easier communication of any potential problems. Our scanning software also has

feature recognition capabilities for dimensional inspection and GD&T analysis.

Pivot Solutions will also provide 3D viewing software to support a paperless inspection system.

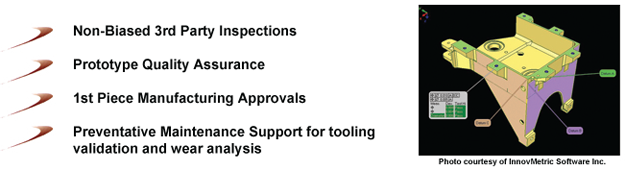

We provide all the necessary data for the following:

Our portable contact-probe CMM inspection system is ideal for “pro-active” rather than “re-active”, in-process measurements and inspections. The flexibility of our system allows you to push inspections back into the equipment rather than after the product is made, thus reducing unnecessary equipment downtime and scrap. We utilize CMM software which can interface directly with many different CAD formats. We have the ability to measure components too large for stationary CMM machines by using a leap frog function. Also, our service can be utilized for trouble shooting equipment failures and in preventative maintenance programs, providing concrete data for pro-active measures.

Speed up your quality inspections

Correct quality deviations prior to full production

Simplify your complex measurement

Pro-actively validate your equipment efficiency

Launch your new products quicker

Enhance your preventative maintenance program

Call us and let the team at Pivot Solutions Inc. help you with your inspections today.

Our Other Services

Inpections & ValidationsReverse Engineering

Computer Aided Design

3D Rapid Prototyping

CNC Machining Services